The Importance of Volume Verification

…and how we can help.

Why Your Sample Volumes Might Not Be What You Think They Are (and What to Do About It)

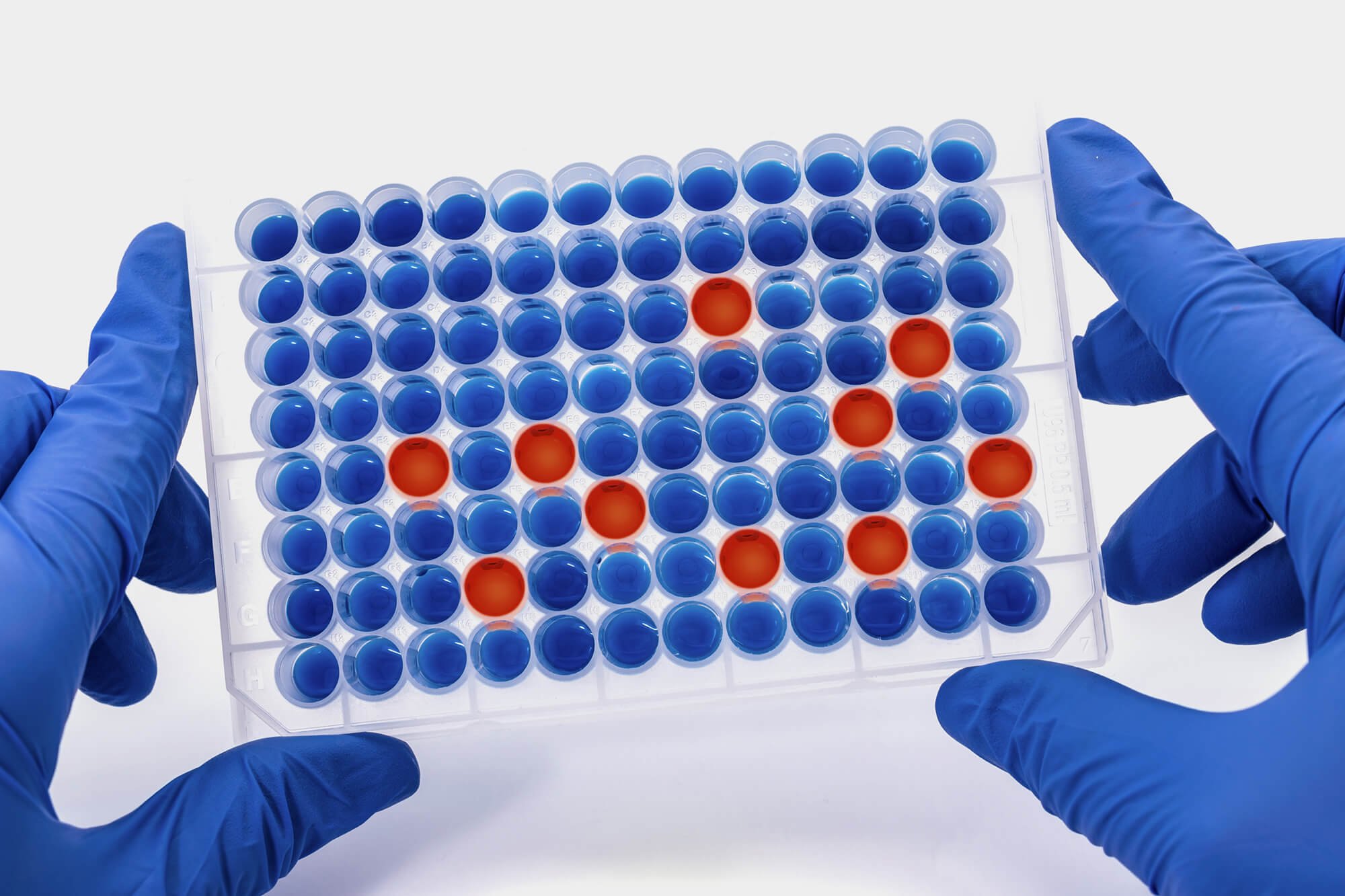

In today’s labs, accurate liquid volume measurement is critical—but it’s often taken for granted. Whether you're developing assays, validating instruments, or managing high-throughput workflows, small errors in sample volume can lead to major downstream consequences. And the truth is: your actual sample volumes may not match what you think you're dispensing.

In this article, we break down 10 common reasons for inaccurate liquid volumes, explain why it matters, and show how Meniscense’s VolumeSense instruments offer a smarter way to measure.

10 Reasons Your Sample Volumes Might Be Off

Liquid Handling Inaccuracy

Even calibrated liquid handlers aren’t perfect. Over time, small performance drifts lead to inconsistent volumes, especially in multi-step or multi-plate processes.

Tip Retention or Incomplete Dispense

Some liquid always clings to the pipette tip—especially with viscous or sticky reagents—leaving less in the well than you expect.

Evaporation During Processing

Open plates, high temps, or long run times cause evaporation. This is especially problematic in small-volume assays or slow batch processing.

Pipetting Technique Variability

Manual and semi-automated workflows introduce variation from user technique—pipette angle, immersion depth, or timing can all affect results.

Cross-Platform Differences

Using different liquid handlers or robotic platforms across labs? Even small design or software differences can lead to measurable inconsistencies.

Clogged or Partially Blocked Tips

A single blocked tip can quietly ruin an entire run. These issues often go unnoticed until it’s too late—unless you’re measuring volumes directly.

Calibration Drift

Liquid handlers and instruments need regular calibration. Missed or infrequent checks lead to creeping inaccuracies across time and instruments.

Liquid Properties

Viscosity, surface tension, and bubbles all affect how a liquid dispenses. Assumed volumes don’t account for these dynamic variables.

Thermal Expansion or Contraction

Temperature fluctuations—between equipment or rooms—can subtly alter volume delivery without any warning.

Plate or Well Geometry Variation

Minor variations in labware design (especially across vendors or batches) can lead to inconsistent fill levels and meniscus heights.

Why Volume Accuracy Is So Critical

Volume errors—no matter how small—can:

Compromise assay reproducibility

Trigger failed validation steps

Waste precious reagents and time

Cause inconsistencies across sites or operators

Undermine regulatory compliance and data integrity

And in high-throughput labs, small errors get amplified. This is where volume verification becomes a crucial safeguard—not just a nice-to-have.

How VolumeSense Solves the Volume Mystery

Meniscense designed the VolumeSense and VolumeSense DW instruments to eliminate the guesswork and bring true, real-time volume verification into the lab.

Using optical interferometry, VolumeSense directly measures the liquid meniscus—the actual volume in each well—without touching or altering the sample. It works with everything from standard microplates to deep well labware.

Key Features & Benefits of the VolumeSense Line:

Non-contact, non-destructive volume measurement

Dye-free: No interference with chemistry or added reagents

Compatible with a wide range of labware (including deep well plates)

Supports complex samples (turbid, viscous, or particulate)

Fast measurement: ~1 min for a 96-well plate

Automation-ready: Easily integrates via API

No consumables or proprietary tips/plates required

Accurate, reproducible data you can trust

Want to Know What You’re Really Working With?

Contact Meniscense to Start the Conversation

If you're unsure about the volumes in your process—or just want to add an extra layer of quality control—let's talk. Meniscense works directly with labs to evaluate workflows, verify labware compatibility, and identify opportunities for in-process inspection and volume monitoring.

Fill out the form below to reach out to our team. Let’s collaborate on improving accuracy, reducing risk, and driving confidence in your data.